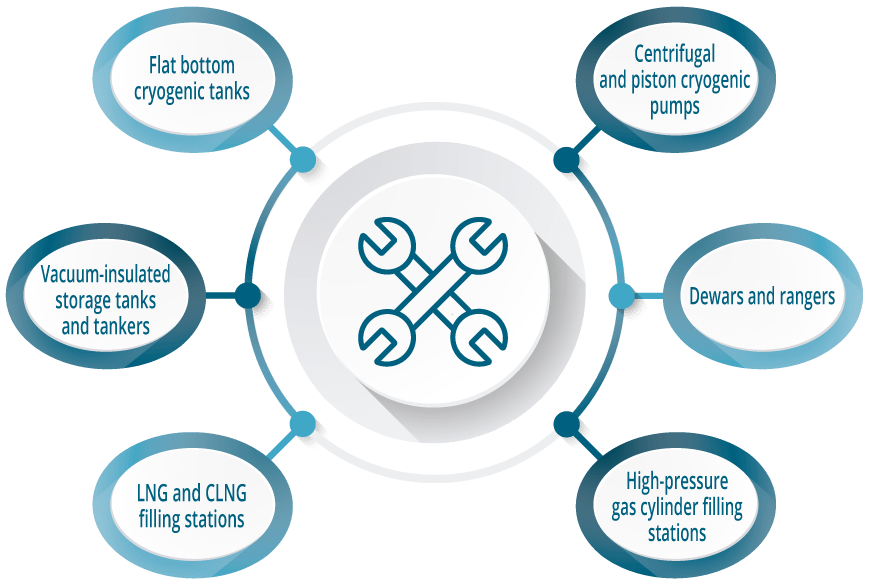

Maintenance and After-Sales Services

Our priority is to provide personal, speedy and high-quality service to the cryogenic industry.

Professional service to you. Our vocation

Our staff is made up of professionals specialised in cryogenic installations and machinery. They are our most valuable asset, and our investment in their continuous training is the proof.

Thanks to them and to our technology, we can offer our customers end-to-end service tailored to their unique requirements, always meeting the highest quality standards.

At Cryospain, we have a workshop and clean room dedicated exclusively to the repair and maintenance of cryogenic pumps.

We have both the team of professionals and the highly specialized technical means for all types of repairs, which we can perform either in our workshop or at our clients’ facilities.

In order to minimize delivery times, we have a wide range of parts for cryogenic, centrifugal and piston pumps permanently in stock.

Repair of centrifugal and piston cryogenic pumps

Discover how we repair cryogenic pumps in this video

Helium Leak Detection

Leaks in fluid distribution networks are the root of crippling economic losses and negative environmental impact. It is therefore crucial to locate them quickly and accurately in order to repair them as soon as humanly possible.

There are several methods of leak detection and different tests to verify them. One of the methods most highly valued by experts for its accuracy, efficiency and a range of other advantages is helium leak detection.

Helium leak detection is the most sensitive, reliable and safe leak detection method on the market, as helium is the second smallest molecule in the periodic table, as well as being an inert, non-toxic gas.

Watch our video: Helium leak detection guide

Cryogenic equipment repair and vacuum recovery

The maintenance of DEWARS and RANGERS must be both frequent and exhaustive to comply with use and safety regulations.

In our specialised workshop, active since 2005, we perform comprehensive maintenance of these portable vacuum-insulated vessels (PGS) and other types of tanks. We have repaired more than 2,000 units.

We are specialised in:

- Helium leak tests of inner and outer vessels using mass spectrometer (leak detection)

- Heating during vacuum process

- Vacuum using high vacuum pumps, stabilization and measurement of final vacuum vale

- Tightness test of the valves using gaseous nitrogen and soapy water method

- Review / modification of manometer and value

- Review / replacement of safety valves

- Final tightness test of the equipment with gaseous nitrogen and re-certification

The temperature differentials cryogenic tanks are subjected to means their parts inevitably suffer wear and tear. Your components must therefore be checked and replaced regularly. Our framework contracts with industry-leaders and more than 200 repaired units are the proof of our experience in this area.

Our mission is to guarantee our customers that their cryogenic storage equipment stays running like it did the first day.

Comprehensive and preventive/ predictive maintenance of cryogenic plants

High pressure gas cylinder filling stations/ LNG and CNG refuelling stations

More and more customers rely on Cryospain for 360º service covering preventive maintenance, periodic inspection and repair of their refuelling stations and pressure equipment.

Following ITC EP4 and ITC EP6 guidelines, we perform pressure tests and check valves and safety and control elements to ensure your installations meet current regulations.

We carry out level A, B and C inspections, each with their corresponding tests and trials.

Clients also call on us for our urgent corrective maintenance service; we can quickly replace broken or worn elements, to ensure the continuous operation and safety of the installations.

Download our file: Flat bottom cryogenic tank repair projects

In this file you will find the overhaul and maintenance of FBT:

Preliminary study | Design | Delivery | On-site supervision | Additional services

Flat bottom cryogenic tank repair projects

Located outdoors, flat bottom cryogenic tanks are exposed to everything weather can throw at them. As a result, these installations demand regular maintenance.

The overhaul and maintenance of these vessels includes leak detection and repair, repair and fabrication of control panels, inspection and repair of safety devices, pneumatic and electrical installation, etc.

We are able to carry out these works either in our workshop or on-site at your facility, the choice is yours.

Kontaktieren Sie uns

Kontaktieren Sie uns