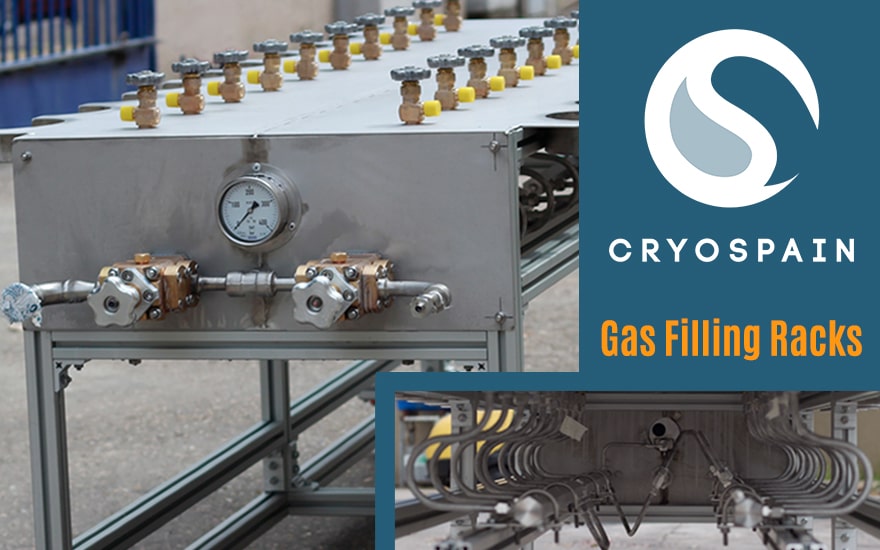

In this article, we’d like to show you an installation we completed for a family-owned gas distribution company in the Canaries, Spain

Cryospain’s reputation in our sector grows with each installation we successfully carry out for our clients. For this job building gas filling racks, we demonstrated to our client two of the guiding principles behind this success: safety and tailored solutions. This customized filling station not only fulfills all the requirements and regulations, it also meets the unique needs of the client.

Top-of-the-line equipment for a job well done

Cryospain prides itself on our skills and expertise, but also on using the latest technology. The following is a list of the equipment that make up the gas filling racks for our client’s customized filling station:

- 1 liquid oxygen piston pump for compressing liquefied gases up to 350 barg.

- 4 fixed semi-automatic high pressure filling racks for filling 20 cylinders of up to 50 litres of oxygen.

- 2 20 cylinder filling trolleys adaptable for 5,7 or 10 litre Nitrogen or Argon cylinders.

- High pressure valve system

- Control panel, instrumentation as well as all the safety features required by the regulations.

Tailor-made solutions, Cryospain’s speciality

Each client is unique, so we believe our solutions should be tailored to each client. We were able to give our client the choice of 20, 16 or 12-bottle gas filling racks / trolleys. They could also choose between a wide variety of sizes.

Given that our client’s customized filling station is situated in the Canary Islands, our experts had to “tropicalize” the equipment against the elements. This is because the climate in the region can be very damaging, especially to electrical or electronic components.

Meeting regulations and guaranteeing safety

The gas filling racks met all of the relevant regulations, in particular ITC EP 6 and regulations covering pressure equipment. Cryospain can, however adapt to meet any country’s regulations whenever the situation requires it. Our client can also be safe in the knowledge that we take safety very seriously. Given the gas is extremely dangerous at high pressures, the choice of compatible materials is vital. Crucial too are the strictest levels of cleanliness, ensuring the customized filling station is free of grease or organic residue.

Let us make your projects a reality

If you’d like to speak to our experts about your own equipment needs, contact us today. We look forward to helping take your projects from plans through to launch!

Kontaktieren Sie uns

Kontaktieren Sie uns