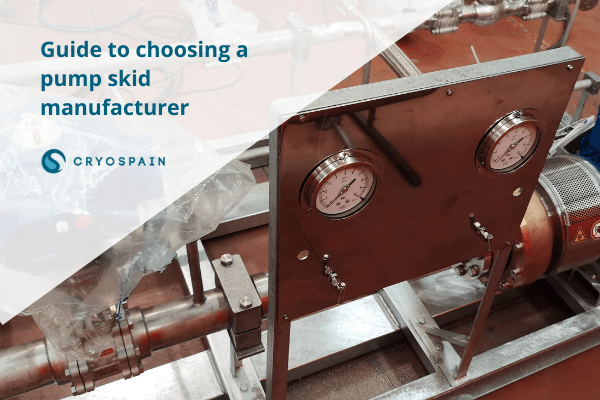

Choosing the right pump skid manufacturer can make a difference between a reliable pump skid equipment and one that produces inefficiencies and an untrustworthy system.

In charge of many key processes across different industries in need of fluid transportation and chemical dispensing, an industrial pump skid must meet several quality and efficiency requirements.

We take a look at them, specifically focusing on cryogenic pump skids and the most important conditions that the right pump skid manufacturer should fulfill.

Things to consider before working with cryogenic pump skids

- Ease of use: the right pump skid system should not only perform correctly, but facilitate its installation, operation and connection, as well as maintenance processes.

- Customization possibilities: as pump skid structures are used across a number of fields, it’s important to find a solution that will match each company’s specific needs. As such, a pump skid for residual water treatment should present a different structure and design than a cryogenic pump skid.

- Pump skids must comply with different standards and certificates, which might vary depending on the system’s location. For instance, the EN 13458 standard is applied to cryogenic pump skids, while the CE 14/68 marking is necessary for equipment operating in Europe.

Keep reading: Pump skids for industrial applications

What to look for in a cryogenic equipment manufacturer

Cryogenic equipment must be specifically designed to keep the necessary low temperatures in a safe and efficient manner that is also cost-effective for companies. Thus, the following are among the most desirable requirements for any company that works as a cryogenic pump skid manufacturer:

Quality Certificates

Being able to comply with national and international standards such as the ones mentioned above provides proof that a pump skid manufacturer is committed to develop quality products.

For example, some of the standards that Cryospain has as a pump skid manufacturer are:

- ISO 9001:2015, ISO 14001:2015, and ISO 45001:2018.

- ERP-2 and 13-B-E62- Category II.

Technology

Devising the right cryogenic pump skid comes hand in hand with using technology to facilitate every operation related to the system. This includes optimized HMI (Human-Machine Interface), as well as intelligent systems that are able to monitor the system’s performance.

Security

Operating cryogenic equipment and substances comes with a number of potential risks and hazards: from asphyxiation, extreme cold, and toxicity to fire and explosions.

A trustworthy cryogenic pump skid manufacturer will have designed their equipment to prevent such scenarios, and can provide staff training in order to guarantee the equipment is safely handled.

Experience

Experience both in local and global markets provides proof that a pump skid manufacturer has developed the skills to successfully respond to diverse challenges. This also includes the transporting of equipment, a potentially hazardous task that can also endanger the newly-acquired system.

Case Study: Tailored Cryogenic Pump Skid in Jamaica

Why choose Cryospain as your pump skid and cryogenic equipment manufacturer?

At Cryospain, we’re a global leading cryogenic equipment manufacturer and pride ourselves in delivering high-quality services and advanced and innovative technical solutions.

We’ve been in charge of developing cryogenic pump skids across the globe, including projects in Germany, Jamaica, France, Switzerland, Puerto Rico and Spain, providing the following benefits:

- We can build equipment based on both European and US standards and certificates

- We provide flexibility and customization, being able to generate tailor-made equipment. In fact, our constant expansion in production capacities has allowed us to be as flexible as possible when creating cryogenic pump skid solutions.

- Every project starts and ends with our clients’ needs in mind, including each project’s unique standards they need to meet.

- In fact, our technical team has a wealth of experience tailoring cryogenic pump skids to the exact specifications of each new challenge. In other words, when our experts design cryogenic equipment, the client is always at the centre of every decision.

- We strive to provide reliability during the product’s whole life cycle. This translates into an efficient after-sale service, covering spare part supply, maintenance or repairs and technical assessment.

- We incorporate state-of-the-art technology in order to guarantee our cryogenic installations are safe and easy to operate.

For instance, we incorporate an HMI (Human-Machine Interface) in pump skids in order to control the entire process in a simple and safe way.

This advanced technology means operators have all the necessary information about the process being carried out in the cryogenic skid at their fingertips, displayed through a color LCD panel. Through this user-friendly and intuitive system, all data related to processes, temperatures, alarms and timings (such as the status of valves, levels, temperatures or cryopump motor performance) is easily accessible in minute detail and real–time.

The HMI translates complex operating variables into practical and actionable information. This provides production line operators and supervisors with a vital advantage in order to coordinate and control the industrial processes generated in the skid system in the most effective way and being able of current insights and context.

At the same time, in case of alarm or error in any cryogenic skid process, the HMI system will instantly alert operators by means of an eye-catching on-screen message. This technology will thus indicate exactly what the error or failure is and where it has occurred. This means potentially costly errors get fixed faster, since the system diagnoses the area, machine, valve or sensor that is failing.

At Cryospain, we are industry leaders in custom engineering projects boasting the very latest technology. If your project needs a cryogenic skid, why not contact our team today? Our more than 20 years of experience mean you can be sure that you’ll be getting the best technical solution that matches your company’s needs.

Contacte-nos

Contacte-nos