Cryospain is proud to announce our latest international project in Edmonton, Alberta (Canada) for the production and supply of Liquid Hydrogen, a green fuel key to the goal of a net-zero economy.

Our latest overseas partnership is something we’re excited about for two reasons. Firstly, it serves to further cement our international reputation in the cryogenics sector. Secondly, our client shares our belief in the power of liquid hydrogen in the fight to reduce harmful emissions. It is an honor to partner with a company that is a true pioneer in developing liquid hydrogen supply chains the world over.

Net-zero: a goal worth working for

Cryospain has long been a champion of the switch to greener fuels like liquid hydrogen. An example of this is our work retrofitting ships and trains to make existing infrastructures less impactful to the environment.

Our partners on this project are passionate about this too. In fact, the hydrogen energy complex they’re building in Edmonton, Alberta, is itself a net-zero plant! At a moment in which Canada is positioning itself to become a world leader in the hydrogen revolution, Cryospain is ready to help make this key project possible.

Cryospain’s piece in a complex and efficient puzzle

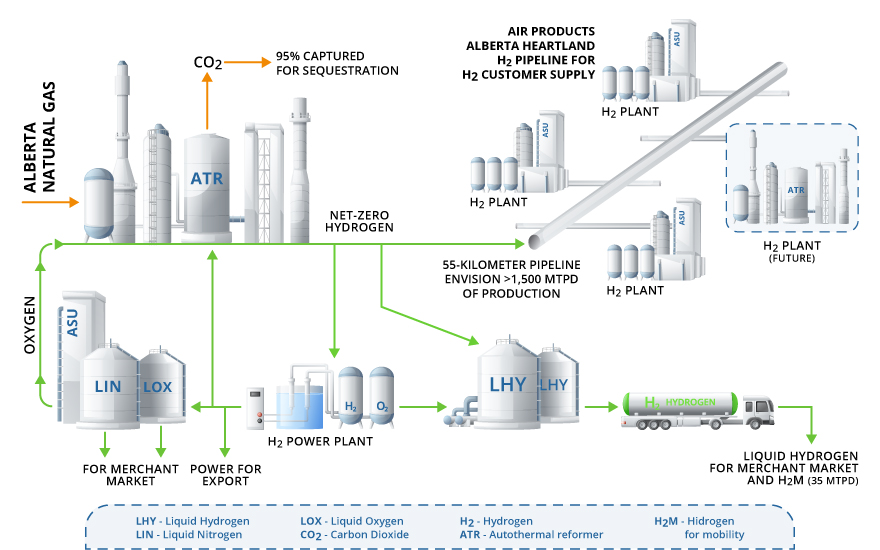

The state-of-the-art complex will feature an air separation unit (ASU) for the oxygen needed to supply an autothermal reformer (ATR). 95% of the CO2 generated will be captured via carbon sequestration. The result is net-zero Hydrogen which the plant splits three ways. Part is sent along a 55-kilometer pipeline to serve other H2 plants and customers via service stations. A second supply feeds a H2 plant which provides power for export before cycling back to the ASU and the ATR. A third portion arrives at the liquid hydrogen storage facility Cryospain’s experts will be helping to build.

Our clients chose to partner with Cryospain because of our more than twenty years as leaders in cryogenic solutions. For this project our engineers will draw on that experience to carry out the design, manufacture and installation of the complex vacuum piping system needed to supply the liquid hydrogen storage facility. The 360-meter network, complete with vacuum-insulated valves, will encompass sizes from DN50-100.

We’ll also build 4 truck loading bays complete with state-of-the-art skids for loading liquid hydrogen at -253ºC. The whole system will be monitored with control panels for maximum safety and efficiency. One of the chief missions of this landmark project is to speed up the adoption of hydrogen as an emission-free transportation fuel across Western Canada. We’re excited to help make that vital change possible.

20 years of experience and expertise for your cryogenic project

If your project requires quality cryogenic components and services, we have the capacity as well as the expertise you need. Why not contact us today or drop us an email at cryospain@cryospain.com. We’re looking forward to making your project a reality.

Kontaktieren Sie uns

Kontaktieren Sie uns