An understanding of the keys to the maintenance of natural gas plants is essential to ensure their safety and longevity.

Why is natural gas plant maintenance important?

Establishing the necessary guidelines for proper maintenance of natural gas plants is essential to ensure that the facilities comply with the established regulations for use and safety.

Lay the foundations and your gas plant will not only comply with occupational risk prevention standards, you’ll be ensuring minimal environmental impact as well.

Regulations you’ll need to follow in your natural gas plants (legal maintenance requirements)

Legal maintenance of natural gas plants encompasses everything you are required to do to comply with existing regulations. You’ll need a deep understanding of involves regulations RD 706/2017, ITC-ICG 04 (applicable to a satellite liquefied natural gas plant) as well as ITC-ICG 05 referring to refuelling stations for gas vehicles.

Recommended reading: Liquefied natural gas (LNG): what it is and how to store it.

Tips for natural gas plant maintenance (preventive maintenance)

Good natural gas plant maintenance means periodic inspections of the installations as well as repair of its refueling centers and pressure equipment. Of course, this must be carried out by specialists, capable of properly checking the condition of the valves and the safety and control elements. If these tests are carried out by the right experts, then compliance with regulations is guaranteed.

How often should you check your equipment?

Natural gas plants must undergo mandatory checks every five years. However, if you want to keep your equipment in perfect working order, you should really insist on preventive maintenance every year.

Scheduled maintenance and functional tests

Includes maintenance of the cryogenic pump, the whole skid and vacuum-insulated equipment check.

Maintenance differences according to the type of plant

The tools and personnel needed for natural gas plant maintenance varies significantly depending on their environment. So you’ll need to make the right choices to ensure proper care for your plant.

What maintenance solutions does Cryospain offer?

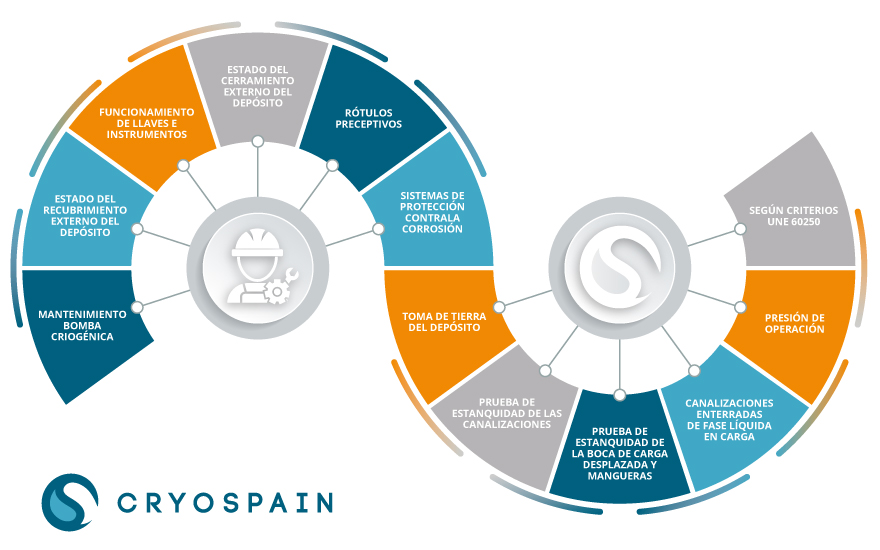

At Cryospain we are specialists in offering industry-leading maintenance solutions for gas plants. Here are some of our star services:

- Periodic maintenance of the cryogenic pump.

- Verification of the correct state of the external coating of the tank, pipes, drains, anchorages as well as foundations.

- Proper functioning of keys, control and measuring instruments.

- The state of the enclosure, access door and closing elements, ensuring no foreign elements are present

- Verifying mandatory signs are both present and in good condition.

- Corrosion protection systems checks.

- Resistance checks on the tank grounding.

- Tightness test of piping in gas phase at operating pressure as well as displaced filler neck and transfer hoses. Tested at 3 bar for 10 min.

- Tightness control with 3 bar test or gas detector on buried liquid phase pipelines under load, except at the loading mouth.

- Checks for tightness at operating pressure.

- Pressure testing according to the criteria of the UNE 60250 standard regarding tests and trials, which you need to carry out every 15 years.

Natural gas plant maintenance done right

All these maintenance solutions allow us to guarantee your plant complies with regulations while also ensuring its safety and long life. If you need more information, contact us and our technical team will take care of everything you need.

Kontaktieren Sie uns

Kontaktieren Sie uns