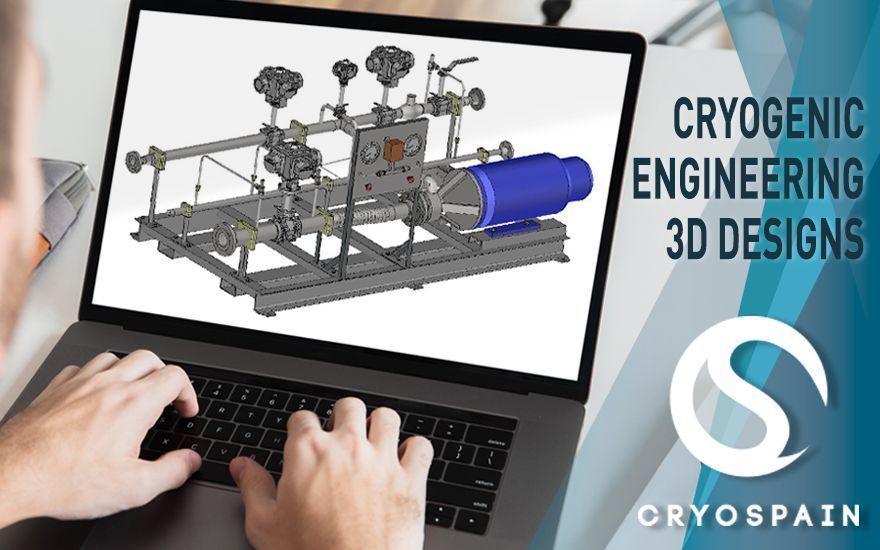

Cryospain’s experts take things beyond 2D when designing cryogenic engineering projects for our clients

At Cryospain, we’re experts in carrying out cryogenic projects. Key to this is our highly-qualified engineering and cryogenic design department in charge of making each job a success.

Step by step…

To guarantee the success of an engineering project, it’s vital to complete the task in stages. Firstly, we need to understand our client’s needs and study them in detail. Only then can we begin to put together the plans for the project using cutting-edge tools. Finally, we can polish the cryogenic designs we need to achieve an efficient, reliable, safe and attractive solution.

Our industrial designers and draftsmen are constantly re-training in the highest standards of effective technical solutions. The search for excellence in our cryogenic designs is one of our pillars as a company.

We see in 3D

Our designers can see every detail before it exists thanks to virtual renders, real 3D drawings, a technique that places Cryospain firmly at the vanguard of cryogenic design.

Our advanced engineering is capable of planning, creating and presenting a client’s cryogenic project en 3D scala 1:1. So our customers get to understand how our solution will work for them by seeing it in its real environment.

Our 3D projects give clients 20/20 vision on the product or solution we’re providing for their unique needs before a single component is built.

Cutting-edge technology: a crucial element of our work

Our drafting and design team works with the best computer aided design software. Standing out among them are Solid Works and Inventor, along with different rendering programs that capture the objects, equipment and installations created in 3D virtual reality. These include pipelines, flat bottom tanks, gas tanks, control panels, gas filling stations, hydrogen processing systems…

Cryospain’s choice to invest in the latest tech, coupled with our over 18 years of experience explains how we’ve come to be a leading company in our sector.

Kontaktieren Sie uns

Kontaktieren Sie uns