This latest project to build crucial elements of an air separation unit (ASU) showcases Cryospain’s productive capacity

In this article, we want to use this containerized ASU project as an example to highlight a specific kind of client. Many of you come to us with little more than an idea, a need. You tell us what your project requires and then we handle everything. This includes planning, drawings, calculations, 3D modelling and all the elements that come before manufacture and assembly. In these cases, our strength lies in our ability to provide tailored, end-to-end service.

This client, however, a recurring customer and a world leader in our sector, takes care of the design and planning themselves. They provide our team with comprehensive engineering documentation, covering the design elements down to the last detail.

In these cases, Cryospain’s own production capacity and human capital are the key factors that set us apart. We’ll talk about that in more detail here, but first let’s look at the project itself.

What is a containerized ASU?

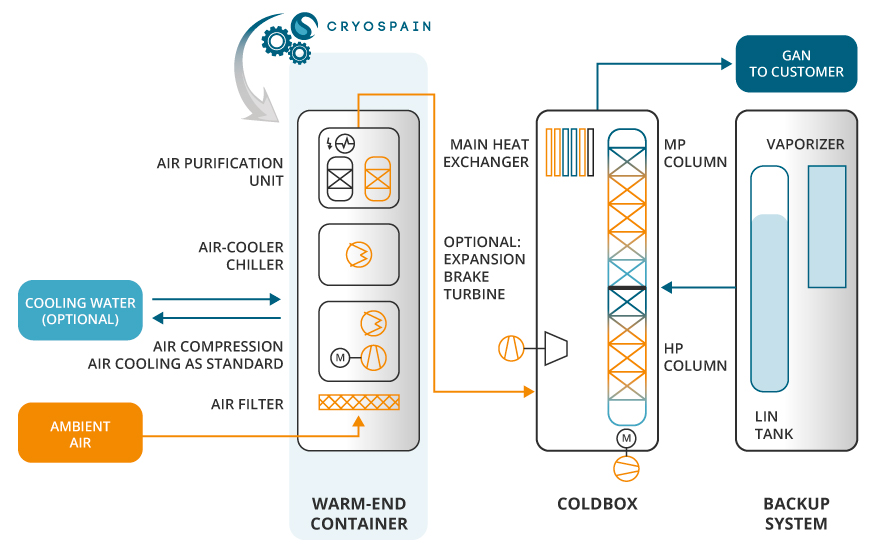

Containerized ASUs are unique in that they are prefabricated. This not only makes transport, assembly and commissioning far easier, it also means they can be tested before arrival at your facility so they can be installed and started up far faster. The purpose of these modular units is to produce nitrogen and oxygen from the air around us.

The type of containerized ASU plant for which Cryospain will be providing the components boasts cutting-edge rapid cooling and refrigeration technology, making it cost-effective as well.

Cryospain is currently kicking off another project that leverages the concept of building equipment within modular units. To see how we’re helping disruptive startup SpaceDreamS transform the space travel industry in Europe and beyond, read on here.

Specialized manpower and our very own production facilities

Our client chose to partner with Cryospain once again for our specialized manufacturing capabilities.

One side of this is our most important resource: our people. We have skilled cryogenic experts who can draw on more than twenty years of experience in the cryogenic sector. Our teams of experts handle procurement of materials, assembly of equipment, electrics and piping, as well as vital elements like factory acceptance testing (FAT) for the containerized ASU’s components.

On the other hand is our production capacity. Cryospain has two large-scale workshops in our native Madrid. Our first, in the industrial hub of Pinto, has since 2021 been accompanied by another in Getafe, whose characteristics and capacity you can check out here.

The two sites have a combined 2600m2 dedicated to taking our clients’ projects from blueprints to reality with the highest quality standards. For this containerized ASU we’ll be bringing this production capacity to bear to expertly manufacture every element our client needs.

Cutting-edge equipment to be built in our workshops

We’ll be handling most of the elements of this containerized ASU. Work will start first on the TSA Air Treatment Unit. TSAs contain absorbers that remove moisture from the air, as well as filters and exchangers. Cryospain manufactures this equipment including all the components. We then install the elements and weld connections between the equipment with all the necessary piping. Finally, our team runs exhaustive tests on all the equipment before sending it to the customer for installation.

Cryospain will also build a skid to house all the valves and control instrumentation. And the last element will be the electrical container, whose purpose is to house all the systems necessary to supply electricity to the containerized ASU.

Whatever your project needs, we can take care of it

Whether you need a specific piece of equipment or service or a more end-to-end turnkey solution, talk to us, we’re looking forward to working with you.

Kontaktieren Sie uns

Kontaktieren Sie uns