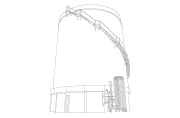

Cryospain is involved in the construction of the Fuel Gas Supply System and the gas venting system for two cruise ships of a leading global luxury tour operator.

This represents yet another important contribution to improving the sustainability of the maritime sector. Ehese cruises are expected to cover routes within the maritime emissions control zones indicated in the MARPOL convention. As such, their operation must prevent the emission of sulfur oxides and nitrogen oxides (SOx and NOx) into the atmosphere, typically associated with the combustion of fossil fuels and currently subject to increasingly rigorous regulations.

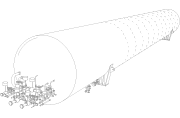

Faced with this, the alternative of natural gas is proposed as an energy source, capable of significantly reducing these harmful emissions. Natural gas will be used in a liquid state, requiring the use of cryogenic tanks (-165 Cº) for storage, as well as vacuum-insulated pipes for transportation.

This is where Cryospain’s role comes into play, involving us once again in a project that advances towards green maritime transport.

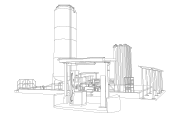

Design of the supply system and venting system: adapting to the project’s requirements

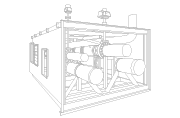

A crucial part of this collaboration has been the design of the Fuel Gas Supply System or FGSS, together with the venting system, a first stage we’ve been 100% involved since January 2023.

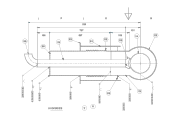

For this, we carried out operations such as the flexibility analysis, the calculation of reactions in supports, routing, segmentation, detailed engineering for manufacturing, and materials specification.

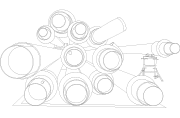

Our proposal also includes a hybrid pipeline with three parts:

- Double Wall Cryogenic Pipe (Vacuum Insulated) for LNG Transportation

- Double wall ventilated pipeline for GN transportation

- Simple cryogenic piping for venting system

In addition to this, the project presents a total of 187 sections of pipe, 119 of which are double-walled. This represents a total of approximately 1200m, including approximately 750m of double-walled cryogenic tubing. More specifically, these are the length details of the pipe to be supplied:

- 1″ 90m

- 2″ 102m

- 3″ 102m

- 4″ 264m

- 6″ 420m

- 8″ 84m

- 10″ 138m

Construction and installation: ensuring the perfect closure

Later comes the construction and installation stages. This process includes manufacturing, installation, initial vacuum of the system (to be done in the shipyard) and testing of the already designed pipeline.

Cryospain also takes care of transportation to two locations for construction in Europe (Italy and Romania), also taking into account that the final works will take place in a third location where the final integration will take place.

Our team will also be in charge of the installation and supervision processes, as well as the helium leak testing and pressure testing. All with the aim of providing a closure for the project in 2026.

Conversely, all stages have taken into account a series of relevant standards and regulations, including Directive 2014/68/EU (European Pressure Equipment Directive), the ASME design code ASME B31.3, the NDE in accordance with ASME V and IGF code. Additionally, we have guaranteed the approval of the RINA Classification Society in processes such as:

- Materials selection

- Certification of material properties

- Certification of welders and procedures qualifications

- Inspection of non-destructive tests (NDE’s) and witnessing of tests in the workshop and in the shipyard

By getting involved in the project comprehensively, at Cryospain we once again confirm our commitment to the most cutting-edge cryogenic engineering at a global level and our ability to adapt to the needs of each project.

Furthermore, in a context in which cryogenics is paving the way for more sustainable technologies in maritime transport and beyond, we reaffirm ourselves as trusted allies to make this transition.

Learn more about our experience in bringing cutting-edge cryogenic engineering to maritime transportation in these success story articles, such as the project to design piping systems for the transportation, storage and injection of liquefied natural gas (LNG) for four cruise ships or this other in which we are in charge of the design and manufacturing process of the vacuum insulated pipes for the retrofit and the new ship with LNG propulsion.