Reciprocating pumps have been a stalwart in fluid dynamics for decades, with their importance underscored by their reliability, versatility and efficiency in various industrial applications.

Grounded in their adaptability, efficiency, and reliability across a range of industrial applications, reciprocating pumps have been at the spotlight as industries evolve and place greater emphasis on precision, energy efficiency, and environmental stewardship.

As such, the current applications of reciprocating pumps ensure they continue to play a pivotal role in meeting demands for efficiency and precision, making them indispensable components in modern industrial processes.

But what are reciprocating pumps exactly, how do they work and what are their recommended applications? Keep reading to find out.

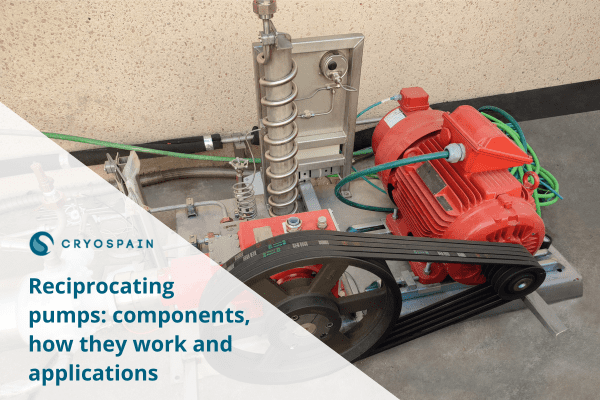

What are reciprocating pumps?

A reciprocating pump is a type of positive-displacement pump that uses a piston or a plunger to displace fluid in a reciprocating (back-and-forth) motion.

As such, reciprocating pumps fall under the broader category of positive displacement pumps, which are in charge of moving a fixed amount of fluid with each cycle of operation.

When compared with other types of pumps, reciprocating pumps provide several advantages which, in turn, make them suitable for the applications we’ll see below. These include:

- The delivery of a precise flow rate at a given speed

- A continuous rate of discharge

- Delivery of fluid at a very high pressure (able to generate up to 69Mpa or 10,000psi)

- Can handle high-viscosity fluids or fluids that contain solids

Keep reading: Guide to choosing a pump skid manufacturer

Different types of reciprocating pumps

Steam pumps

Steam pumps refer to pumps that are powered by steam engines, thus using steam as a driving force to move the reciprocating components (such as pistons or plungers) and thereby transfer energy to the fluid being pumped.

Power pumps

This is a broad term that refers to reciprocating pumps driven by various external power sources, that is, any means capable of providing the necessary energy. These include electrically-driven pumps, gasoline or diesel engine-driven pumps, hydraulic power pumps or pneumatic power pumps, among others.

Metering pumps

These pumps are designed for precise control of flow rates and are typical of industries such as water treatment, chemical processing, pharmaceuticals or various manufacturing processes. The reciprocating piston can be in direct contact with the fluid, or shielded from the fluid diaphragm.

Major components of reciprocating pumps

The basic components of a reciprocating pump typically include:

- Cylinder

- Piston or plunger

- Suction and delivery valves and pipes

- Drive mechanism.

These elements combine in the following working principle:

- During the suction stroke, the piston or plunger moves away from the cylinder’s discharge port, creating a low-pressure zone within the cylinder. This causes the suction valve to open, allowing fluid to enter the cylinder from the suction line.

- On the contrary, during the discharge stroke, the piston or plunger moves toward the discharge port, increasing the pressure within the cylinder. This pressure forces the discharge valve to open, allowing the fluid to be expelled from the pump into the discharge line.

Uses of reciprocating pumps

Reciprocating pumps find application across a wide spectrum of industries, due to their unique capacities.

On the one hand, their ability to handle a variety of fluids (including corrosive and viscous substances) makes them invaluable in processes where different materials and conditions are encountered.

At the same time, they are well-suited for applications requiring high-pressure delivery and precise control.

It’s also worth noting how these pumps excel in situations where the flow rates vary. This capacity of reciprocating pumps to adjust to changing operational requirements makes them ideal for processes that demand flexibility and responsiveness.

Additionally, reciprocating pumps are known for their high efficiency, especially in applications with varying load conditions. This is due to their positive displacement nature, which ensures that a consistent volume of fluid is delivered with each stroke, reducing the need for excess energy to compensate for fluctuations in flow.

You must be interested: Turnkey Pressurized Tank Services

The robust construction of reciprocating pumps makes them well-suited for harsh operating environments. Whether dealing with corrosive chemicals, abrasive slurries, or extreme temperatures, reciprocating pumps demonstrate resilience and durability, minimizing downtime and maintenance costs.

Finally, reciprocating pumps often excel in applications where a high-pressure output is required.

All these capacities combine to make the applications of reciprocating pumps include industries such as:

- Oil and gas production and pipeline

- Water and waste treatment

- Chemical and hydrocarbon processing

Cryospain, supplier of reciprocating pumps for your project

At Cryospain, we’re committed to offer top-class cryogenic equipment for our clients. As such, in addition to the development of cryogenic equipment, we also supply cutting-edge cryogenic technology.

As part of our distribution services for cryogenic pumps from the industry’s most renowned companies, we offer an extensive range of specialized reciprocating pump manufacturers for the use of LNG, hydrogen, and other substances.

Through this service, we put our expertise in cryogenic applications at the service of supplying optimized cryogenic equipment. Our in-depth knowledge of the unique challenges and requirements associated with handling cryogenic fluids thus becomes essential for selecting the right reciprocating pumps that can operate effectively in whatever requirements our clients present.

By combining cryogenic engineering expertise with a focus on customization, materials selection, safety compliance, testing, and ongoing support, we’re able to provide reciprocating pumps that meet the specific needs of industries dealing with cryogenic fluids.

Additionally, our cryogenic pump maintenance services take into account how incorrect processes may result in poor performance, repeated part replacements and a reduced service life. As such, we’re also able to provide top-notch maintenance and after-sale services, being thus involved in guaranteeing our clients’ investments remain cost-efficient.

Looking for the right reciprocating pumps to incorporate to your project? At Cryospain, we can help you. Get in touch with us and speak to our team about how we can help you have access to the best option equipment for your project.

Kontaktieren Sie uns

Kontaktieren Sie uns